With the growth in popularity of CNC milling machines, more and more enthusiasts are taking on complex DIY projects. I´m not talking about machining shiny aluminum souvenirs or nicely finished wooden ornaments. We are seeing a rise in the manufacture of complex parts that require extreme precision.

We have seen truly innovative machines completely manufactured using CNC machining and 3D printers. Many of them harness the power of compressed air or are used to pump water for cooling, making for very interesting engineering feats.

However, the components for these complex contraptions must be carefully machined so they fit tightly, and water or gas pressure remains stable.

Many machinists resort to roll-tapping their pieces. If you picked your standard hole size, and are working with soft materials, you can get away with just having the right tap size.

However, when you’re creating new machines or working with clients who build complex systems with different gauges, roll-tapping becomes a nightmare. Just the thought of cycling through 3 or more tools for each part makes watching paint dry more preferable. And don´t get me started with chip compaction when threading blind holes. Moreover, if you´re working with hard metals and alloys, like titanium or Inconel, you risk breaking your tool inside the part. This can completely paralyze your operation for a while as you go fishing for a tool that will insist it is now an integral part of your piece.

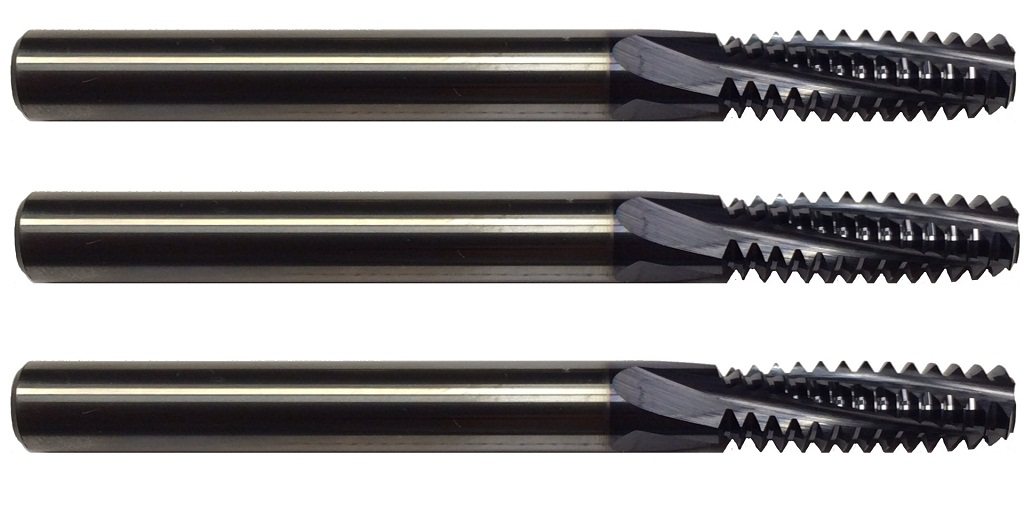

Thread mills are more wieldy. They are generally small in diameter, so you can machine holes with bigger IDs. The same tool will allow you to create threads of different diameters and pitches. Say, you have a piece that needs to be connected to the water main, and then divides the flow through small diameter channels. You can use a multi-form carbide thread mill NPT pipe thread for the main connector, and the same tool will work for the secondary connectors. If you need different pitches, then a single-form thread mill is your best option. Just make sure you program your z-axis correctly to create the right thread pitch. Remember that, with thread mills, it is your machine and not the tool what determines the diameter. No need to change your tools, and no risk of jammed tools inside your part.

To reduce tool breakage, or to make sure your pieces are as close to the print as possible, we recommend using carbide thread mills. The material is heat resistant and extremely rigid. It also maintains its sharpness more effectively than steel tools, allowing you to keep going for long periods.

Carbide thread mills can also create female pipe threads, chamfer the hole, or even convolute the bottom portion of your thread. That’s something impossible to do with traditional taps.

Now, finding the right tools for the job can be a bit tricky. We are used to the dime-a-dozen steel variety that can be found in every hardware store. But if you want a tool that can handle high speeds, high temperatures, and retain its hardness and integrity, we recommend using carbide thread mills. Online Carbide manufactures incredibly reliable carbide tools, and they have the most competitive prices we have seen. Visit their website or give them a call today.

For more information about Carbide End Mill Set and Single Pitch Thread Mills Please visit: Online Carbide.