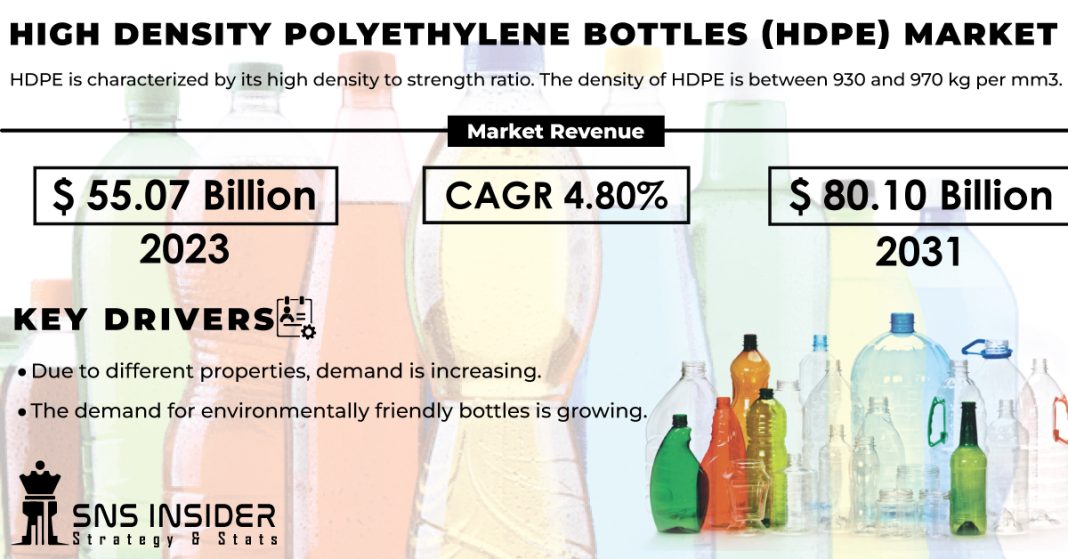

“According to the SNS Insider report, the HDPE Bottles Market Trends valued at $55.07 billion in 2023, is projected to soar to an impressive $80.10 billion by 2031, exhibiting a steady compound annual growth rate (CAGR) of 4.80% during the forecast period of 2024-2031”

This significant growth trajectory is fueled by a confluence of factors, including the expanding applications of HDPE bottles, the shift towards eco-friendly packaging options, and the material’s superior properties that cater to evolving consumer and regulatory demands.

Versatility in Cap Types: Meeting Diverse Packaging Needs

The HDPE bottles market offers an extensive array of cap types, each designed to serve specific product requirements and enhance user experience. Snap closures provide convenient, tamper-evident sealing for products ranging from condiments to household cleaners. Disc top closures, popular in personal care products, offer controlled dispensing and a sleek appearance. The growing preference for on-the-go lifestyles has boosted demand for dispensers and push-pull closures, particularly in beverages and sauces.

Screw closures remain a cornerstone of the market, valued for their secure sealing and reusability across various applications. Meanwhile, droppers cater to precise dosage needs in pharmaceuticals and essential oils, while spray closures dominate in cleaning products and cosmetics, providing targeted application.

This diversity in cap types not only demonstrates the adaptability of HDPE bottles but also underscores the industry’s commitment to innovation in meeting the nuanced needs of different sectors and consumer preferences.

Download Free Sample Report@ https://www.snsinsider.com/sample-request/3916

Neck Types and Capacity: From Portability to Bulk Storage

The HDPE bottles market segments into wide mouth and narrow mouth variants, each serving distinct purposes. Wide mouth bottles facilitate easy filling and access to contents, making them ideal for powders, granules, and viscous liquids. Narrow mouth bottles, conversely, offer controlled pouring and are prevalent in beverages, condiments, and liquid medications.

Bottle capacity plays a pivotal role in market dynamics, with options ranging from less than 30 ml for sample sizes and travel kits to over 1 liter for bulk storage and industrial use. The 101-500 ml category currently dominates, driven by its suitability for everyday consumer products like shampoos, detergents, and cooking oils. However, the 31-100 ml segment is witnessing rapid growth, fueled by the travel and hospitality sectors’ demand for TSA-compliant packaging.

Visibility and Barrier Properties: Balancing Protection and Aesthetics

HDPE bottles are available in opaque and translucent variants, catering to different product visibility needs. Opaque bottles, which shield contents from light exposure, are essential for preserving the integrity of light-sensitive products such as dairy, pharmaceuticals, and certain chemicals. Translucent bottles, offering a glimpse of the contents, are popular in personal care and food products where visual appeal can influence consumer purchasing decisions.

The market further distinguishes between low-barrier and high-barrier HDPE bottles. Low-barrier options suffice for many applications, while high-barrier bottles incorporate additional technologies like multilayer structures or oxygen scavengers to extend shelf life and protect against moisture, gases, and contaminants. This segmentation reflects the industry’s response to the increasing demand for packaging that ensures product longevity without compromising on recyclability.

Application Diversity: From Kitchen to Laboratory

The versatility of HDPE bottles is evident in their wide-ranging applications. In the food and beverages sector, these bottles package everything from milk and juices to edible oils and condiments, benefiting from HDPE’s food-grade safety and resistance to leaching. The personal care and cosmetics industry leverages HDPE’s moldability and chemical resistance for shampoos, lotions, and color cosmetics.

Homecare and toiletries represent another significant market share, with HDPE bottles housing detergents, cleaners, and sanitizers—products that demand durability and child-resistant features. The chemical industry relies on HDPE’s exceptional chemical resistance for safely containing solvents, acids, and speciality chemicals.

Moreover, the pharmaceutical sector is a growing end-user, drawn to HDPE’s ability to meet stringent regulatory requirements and provide tamper-evident, sterile packaging for over-the-counter and prescription medications.

Regional Insights: Mature Markets and Emerging Powerhouses

North America and Europe currently lead the HDPE bottles market, driven by established consumer goods industries, stringent packaging regulations, and high environmental consciousness. However, the Asia-Pacific region is poised for the most rapid growth, propelled by burgeoning middle-class populations, urbanization, and the expansion of retail and e-commerce channels.

Countries like China, India, and Indonesia are not only major consumers but are also emerging as key production hubs, attracted by lower manufacturing costs and proximity to raw materials. This shift is reshaping global supply chains and fostering innovation in localized packaging solutions.

Sustainability: The New Imperative

As environmental concerns take center stage, the HDPE bottles market is increasingly defined by its sustainability initiatives. HDPE’s high recyclability is a significant asset, with many countries implementing advanced recycling infrastructures to close the loop on plastic waste. Industry leaders are investing in chemical recycling technologies and incorporating post-consumer recycled (PCR) content into their bottles, meeting both consumer demand for eco-friendly products and brand commitments to circular economy principles.

Furthermore, efforts to lightweight HDPE bottles without compromising strength are reducing material usage and transportation emissions. Bio-based HDPE, derived from renewable resources like sugarcane, is gaining traction as a lower-carbon alternative, though scalability and cost remain challenges.

Innovation and Future Trajectories

The HDPE bottles market is a hotbed of innovation, with developments aimed at enhancing functionality, sustainability, and market differentiation. Smart packaging technologies, such as QR codes for product authentication and NFC tags for consumer engagement, are being integrated into HDPE bottles. Advances in barrier technologies are expanding HDPE’s suitability for sensitive products like pharmaceuticals and organic foods.

Design innovations are also prominent, with ergonomic shapes, intuitive dispensing systems, and brand-enhancing decorative techniques elevating the user experience. Additionally, the trend towards mono-material packaging, where caps and labels are also made from HDPE, is simplifying recycling processes and improving recovery rates.

Looking ahead, the convergence of HDPE bottles with Industry 4.0 technologies promises further evolution. From blockchain-enabled traceability to AI-optimized production processes, digital transformation is set to enhance efficiency, quality control, and supply chain transparency.

The e-commerce boom is another catalyst, driving demand for HDPE bottles that can withstand the rigors of direct-to-consumer shipping while minimizing secondary packaging. This trend is spurring the development of more robust, yet lightweight designs that reduce both material use and shipping costs.

Conclusion

The HDPE bottles market’s projected growth to $80.10 billion by 2031 reflects not just quantitative expansion but a qualitative transformation. As it navigates the complexities of global sustainability challenges, diverse industry needs, and ever-evolving consumer expectations, the market is redefining the role of plastic packaging in a resource-conscious world. From the milk jug to the shampoo bottle, HDPE continues to prove its value as a versatile, resilient, and increasingly sustainable material, poised to bottle the future—responsibly.

Other Trending Reports

Polyester Straps Market Analysis

Active & Intelligent Packaging Market Analysis

Digital Printing Packaging Market Analysis

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.